In solar energy polysilicon factories, during the transportation of silicon powder, the valve ball will be easily wrapped by silicon powder, after open and close many times, the valve metal seat will be destroyed very easy and seat become leakage. Because of hardness of silicon powder is very high (Mohs Hardness >7), using life of common materials ball valves normally very short.

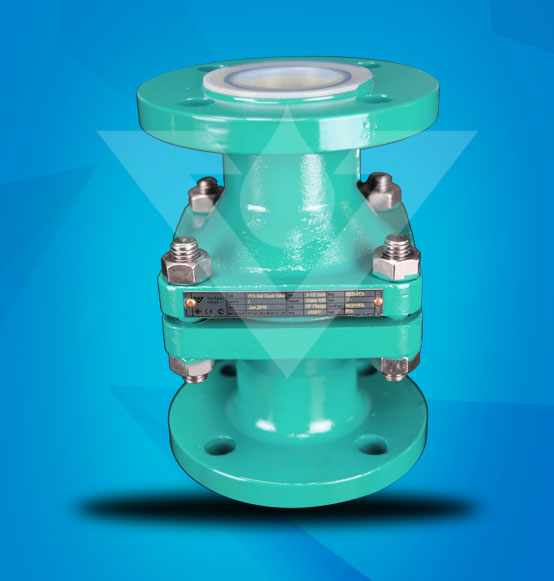

VerSpec Valve Technology Department R&D the New Generation VBC series ceramic ball valve for polysilicon powder transporting. The all wet parts of this type valve all use high pure aluminum oxide or zirconium oxide ceramic materials, hardness of ceramic is a very hard material in the world (HRC 90), only lower than Diamond. 7.3 times harder than stainless steel. So there’s some Verspec ceramic ball valves were served in one severe projects of USA from July, 2015 to now, the using life is 6 times longer than normal material stainless steel ball valves.

What’s the main features of VBC series ceramic ball valve:

1. All valve body and bonnet made by Forged Stainless Steel 304 or ASTM A216 WCB.

2. All valve inner parts are made by Zirconium Oxide or 99.5% very high pure Aluminum Oxide material. Ceramic Hardness ≥ 88, only lower than Diamond. Other type ceramic material also available.

3. High precision machining and grinding ball and seat with advanced technology, makes sealing face touch perfectly and without any leakage.

4. Super high roundness ceramic ball makes operating torque very small.

5. Ceramic ball and seat life are 2-4 times longer than Titanium and Monel Alloy.

6. Lever operator with locking device makes valve in full close or open position.

7. This new generation “VCB” series ceramic ball valve has perfect working performance for severe corrosive media with solid particles. such as Acetic acid, Ammonia, Chlorine(Wet), Clay slurry, Formic acid, Potash slurry, Pulp slurry and sewage etc.

Español

Español