The invention and wide application of Ceramic butterfly valve is an example.

1. The ceramic butterfly valve adopts high-tech new ceramic structural materials to make the sealing parts and vulnerable parts of the valve, which improves the wear resistance, corrosion resistance and sealing of the valve product, and greatly extends the service life of the valve.

2. The use of ceramic butterfly valve can greatly reduce the number of valve maintenance and replacement, improve the safety and stability of the supporting equipment operating system, and save equipment repair costs.

3. The use of ceramic butterfly valve can improve the sealing performance of industrial piping system, can minimize leakage and protect the environment.

4. The raw materials for manufacturing ceramics are wide and the cost is low. The use of aluminum, carbon, silicon and other common elements can produce ceramic materials with superior performance, which can save a lot of metal materials and rare mineral resources.

5 Wear-resistant ceramic valves are mainly used in power, petroleum, chemical, metallurgy, mining, sewage treatment and other industrial fields, especially in the face of severe working conditions such as high wear, strong corrosion, high temperature, and high pressure. Ceramic valves show their excellent performance. Ceramic valves can meet the high wear and strong corrosion environment, especially the outstanding feature is the long service life, the performance-price ratio of ceramic valves is far better than other similar metal valves. With the continuous development and advancement of science and technology, ceramic materials have become more mature and complete in terms of formulation, molding, processing and assembly technology. Ceramic valves are increasingly recognized by the valve industry due to their excellent performance. The successful experience of making ceramic valves can also be applied to a wider range of engineering fields.

Company Profile

2005——Start to produce ceramic lined valve series.

2006——Start to produce rubber seat dome valve, knife gate valve and pinch valves.

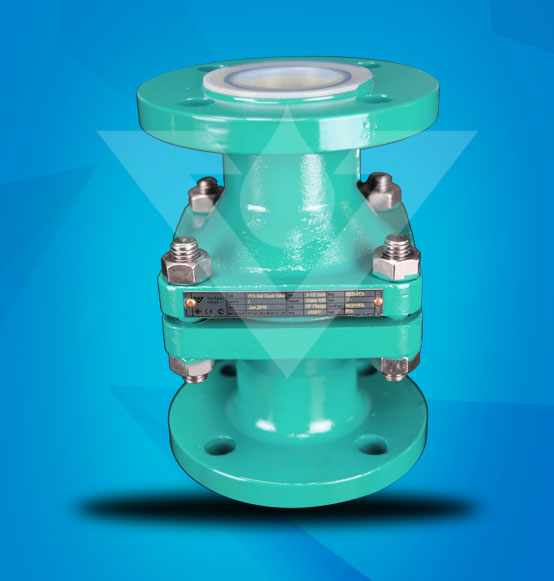

2010——Joint venture start to produce Teflon plastic lined valve series.

2016——VerSpec US warehouse operated in Akensas.

2018——VerSpec Korea branch operated in Cheonnam.

2019——VerSpec India and VerSpec Mexico start operating.

Tel: +86-577-57666870

Fax:+86-577-56769885

E-mail: info@verspec.com

Español

Español